SCB Series Dry-Type Transformer

SCB series epoxy resin dry-type transformer produced by huadong group adopts h-grade epoxy resin as insulating material, low-voltage winding adopts copper tape (foil), high-voltage winding adopts wire, and epoxy resin is poured and cured in vacuum to form a high-strength glass fibre structure.

- DESCRIPTION

- SPECIFICATION

- TECHNICAL & SALES SUPPORT

SCB Series Epoxy Resin Dry-Type Transformer Description:

SCB series epoxy resin dry-type transformer produced by huadong group adopts h-grade epoxy resin as insulating material, low-voltage winding adopts copper tape (foil), high-voltage winding adopts wire, and epoxy resin is poured and cured in vacuum to form a high-strength glass fibre structure. Epoxy resin dry-type transformer has the characteristics of good electrical performance, strong resistance to lightning strikes, strong resistance to short-circuit, small volume, light weight and so on.

SCB Series Epoxy Resin Dry-Type Transformer Working Principle:

The working principle of dry-type transformer is based on the basic principle of electromagnetic induction. When alternating current (AC) flows through the primary windings of the transformer, a changing magnetic field is generated in the iron core. This changing magnetic field produces an induced voltage in the secondary winding through electromagnetic induction, which transfers electrical energy from the primary to the secondary circuit.

The core of a transformer is usually made of high-grade silicon steel sheet, which helps in efficiently transferring the magnetic flux generated in the primary winding to the secondary winding. The windings, usually made of copper or aluminium conductors, carry the alternating current and facilitate the transfer of electrical energy.

The insulation system, usually consisting of epoxy or cast resin, provides electrical insulation and protection for the windings to ensure safe operation. The housing houses all components and provides mechanical support and external protection.

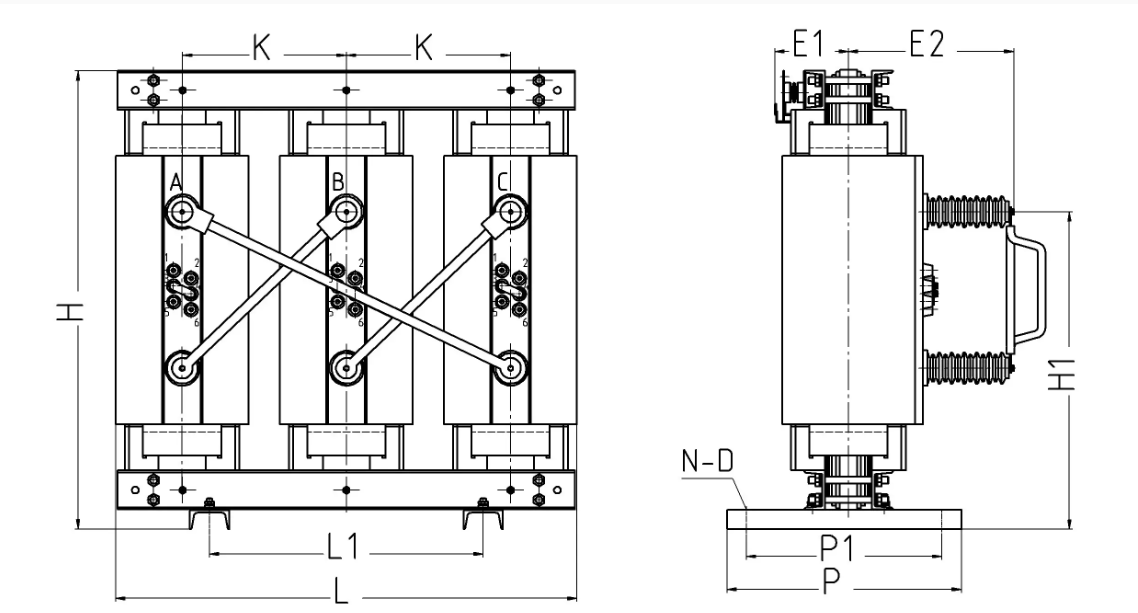

SCB Series Epoxy Resin Dry-Type Transformer Drawings:

SCB Series Epoxy Resin Dry-Type Transformer Features:

- Safe and reliable: cast with epoxy resin and other insulating materials, it has excellent insulation and fireproof performance, effectively preventing electrical faults and fire accidents.

- Energy saving and environmental protection: SCB series dry-type transformer meets the national energy efficiency standards, has low loss and noise level, which is conducive to energy saving and environmental protection.

- Convenient maintenance: compact structure, small volume, easy to install and maintain. At the same time, the dry-type transformer does not need oil immersion, avoiding the problem of oil leakage and pollution of the environment.

- Strong adaptability: it can be used in a variety of harsh environments and climatic conditions, such as high temperature, humidity, salt spray and other environments, with strong adaptability and stability.

SCB Series Epoxy Resin Dry-Type Transformer Selection Of Protective Shell:

The housing material is made of stainless steel or aluminium alloy. Protection classes up to IP20 and IP23 are available. IP20 enclosures provide further safety by preventing solid foreign objects with a diameter of more than 12.5 mm from entering the transformer. IP23 enclosures also prevent water droplets from flowing in at an angle of 60° to the vertical line and are suitable for outdoor operation.

The temperature control system consists of a temperature controller and a PTC temperature measuring element mounted at the hottest point of the product, i.e. at the upper end of the low-voltage winding, to realise the temperature measurement and control of the transformer. If the temperature of the transformer winding is too high due to overload operation or faults, the temperature controller will issue an alarm signal and trip the circuit automatically when the temperature exceeds the safety value. When forced air cooling is used, the temperature controller determines the input or switching of the cooling fan according to the winding temperature. The temperature display system directly indicates the hot spot temperature of the windings during transformer operation and can be used in combination with a temperature control system.

SCB Series Epoxy Resin Dry-Type Transformer Applications:

Our company produces SCB series epoxy resin dry-type transformer introduces the advanced and mature technology and production process in Portugal, adds Germany’s most advanced George iron core cross-cutting production line and Germany Hedrich vacuum casting equipment, product design and manufacturing in the industry leading position.SCB series dry-type transformer is widely used in the following fields:

- Power system: as the key equipment of power system, used for power transmission and distribution.

- Industrial field: to provide stable power supply for various industrial equipments, such as machine tools and production lines.

- Commercial buildings: to provide power support for high-rise buildings, commercial centres, etc., to ensure their normal operation.

- Public facilities: such as hospitals, schools, libraries and other public facilities to ensure the stability and reliability of their power supply.

SCB Series Epoxy Resin Dry-Type Transformer Specification

| Rated Capacity (KVA) | No Load Loss (W) | Load Loss (W) | Impedance(%) | Vector Group | Extend Connection | ||

| B(100) | F(120) | H(145) | |||||

| 30 | 170 | 670 | 710 | 760 | 4 | Yyn0 or Dyn11 | ±5% ±2*2.5% |

| 50 | 240 | 940 | 1000 | 1070 | |||

| 80 | 330 | 1290 | 1380 | 1480 | |||

| 100 | 360 | 1480 | 1570 | 1690 | |||

| 125 | 420 | 1740 | 1850 | 1980 | |||

| 160 | 480 | 2000 | 2130 | 2280 | |||

| 200 | 550 | 2370 | 2530 | 2710 | |||

| 250 | 640 | 2590 | 2760 | 2960 | |||

| 315 | 790 | 3270 | 3470 | 3730 | |||

| 400 | 880 | 3750 | 3990 | 4280 | |||

| 500 | 1040 | 4590 | 4880 | 5230 | |||

| 630 | 1200 | 5530 | 5880 | 6290 | |||

| 630 | 1170 | 5610 | 5960 | 6400 | 6 | ||

| 800 | 1360 | 6550 | 6960 | 7460 | |||

| 1000 | 1590 | 7650 | 8130 | 8760 | |||

| 1250 | 1880 | 9100 | 9690 | 10300 | |||

| 1600 | 2200 | 11000 | 11700 | 12500 | |||

| 2000 | 2740 | 13600 | 14400 | 15500 | |||

| 2500 | 3240 | 16100 | 17100 | 18400 | |||

lf you have any further requests or questions

TECHNICAL & SALES SUPPORT

If you have any questions, please contact us. We’ll do our best to help.