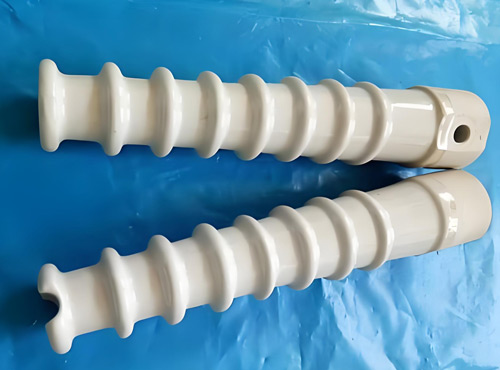

Lightning Protection Composite Insulator

Lightning protection composite insulator is a new type of combined structure of arc-proof insulator, which is mainly composed of insulating shroud, compression nut, briquetting block, moving briquetting block, upper metal cap, composite insulator, arc striking rod, insulating sleeve and The lower metal foot is composed of the same, and the arc striking rod and the upper metal cap are assembled and integrated into one body.

- DESCRIPTION

- SPECIFICATION

- TECHNICAL & SALES SUPPORT

Lightning Protection Composite Insulator Description:

Lightning protection composite insulator is a new type of combined structure of arc-proof insulator, which is mainly composed of insulating shroud, compression nut, briquetting block, moving briquetting block, upper metal cap, composite insulator, arc striking rod, insulating sleeve and The lower metal foot is composed of the same, and the arc striking rod and the upper metal cap are assembled and integrated into one body. When a lightning strike occurs, the arc striking rod and the lower metal leg are discharged, so that the freewheeling power frequency arc is moved to the arc striking rod to burn, thereby protecting Insulated wires are not damaged. Lightning composite insulators are mainly used to prevent overhead insulated wires from being disconnected by lightning strikes, as well as being used as protective devices for power detection and temporary grounding during maintenance and construction, and are suitable for copper and aluminium overhead insulated wires.

Lightning Protection Composite Insulator Feature:

- The moving briquetting block and the briquetting block are assembled by a dovetail method, so that when the wire moves due to thermal expansion and contraction, the moving briquetting piece moves, thereby preventing the wire from being scratched by the wire clip.

- The composite insulator has better insulation performance than the electric porcelain insulators such as PS-15, and its creepage distance is large, which improves the anti-fouling level of the insulator, and can meet the anti-fouling requirements of the majority of users for the insulator.

- The insulating cover is made of organic composite material, which has good insulation performance, anti-aging performance and flame retardant performance. It is mounted on the outside of the upper metal cap to provide insulation protection.

- This product has a puncture-type piercing structure, which is convenient to install and construct. It does not need to strip the insulator wire insulation layer to avoid water ingress and corrosion of the core, which can greatly reduce the labor intensity of the operator.

- A unique structure that prevents birds from causing short-circuit hazards to overhead conductors.

Lightning Protection Composite Insulator Wire Clamping Method:

-

- ◆ Puncture type wire clamping method:

- 1. aluminium alloy torque nut fastening method: the insulated wire parallel into the groove of the clamp, first hand tighten the torque nut, and then use the socket plate hand alternately tighten evenly until the top of the torque nut falls off, and then the insulating sheath can be assembled on the clamping fixture.

- 2. Ordinary nut fastening method: according to the cross-section of the wire and the weather temperature set torque spanner torque value: 20 ~ 35NM, alternately and symmetrically tighten the 2 pressure nuts with a torque wrench, until the spanner screwed to the set torque spanner torque value can be, and then tighten the ready to tighten the nut to prevent the pressure nut from loosening, and then insulating sheath assembled in the clamping fixtures on the wire.

- ◆ Non-penetrating clamping method:

- Strip a section of insulated wire about 65 ~ 80mm wrapped with aluminium tape embedded in the clamping fixture, use a spanner to tighten the pressure nut to drive the pressure block seat compression wire can be, and then the insulating sheath can be assembled on the clamping fixture.

Lightning Protection Composite Insulator Specification

| Model | Rated Voltage | Insulated conductor cross section mm2 | Lightning full-wave impulse withstand voltage (peak) kV | 1min industrial frequency withstand voltage (with limit) kV | Industrial frequency arc current (RMS) KA | Rated bending withstand load KN | Minimum nominal creepage distance mm | Remarks | |

| Dry | Wet | ||||||||

| FEG-12/5 | 6-12KV | 50/240 | 75 | 42 | 30 | 12.5 | 5 | 360 | Puncture type (triangular arrangement) |

| FEG-12/5A | 6-12KV | 50/240 | 75 | 42 | 30 | 12.5 | 5 | 360 | Puncture type (vertical arrangement) |

| FEG-12/5B | 6-12KV | 50/240 | 75 | 42 | 30 | 12.5 | 5 | 360 | Piercing (Triangular) |

| FEG-12/5C | 6-12KV | 50/240 | 75 | 42 | 30 | 12.5 | 5 | 360 | Puncture (Vertical) |

lf you have any further requests or questions

TECHNICAL & SALES SUPPORT

If you have any questions, please contact us. We’ll do our best to help.