Amorphous Alloy Dry-Type Transformer

The SCBH series amorphous alloy dry-type transformer is a transformer made of amorphous alloy. The metal atoms of amorphous alloy materials are arranged in a disordered amorphous state, and their demagnetization and magnetization processes are easily completed, resulting in lower core losses than silicon steel materials and achieving high energy-saving effects.

- DESCRIPTION

- SPECIFICATION

- TECHNICAL & SALES SUPPORT

Amorphous Alloy Dry-Type Transformer Introduction:

The SCBH series amorphous alloy dry-type transformer is a transformer made of amorphous alloy. The metal atoms of amorphous alloy materials are arranged in a disordered amorphous state, and their demagnetization and magnetization processes are easily completed, resulting in lower core losses than silicon steel materials and achieving high energy-saving effects. This product combines the advantages of low loss amorphous alloy materials and traditional epoxy resin cast transformers in terms of high insulation and mechanical strength. Its core is made of amorphous alloy strip. Compared with the traditional SCB10 series silicon steel dry-type transformer, the no-load loss is reduced by 75-80% and the no-load current is reduced by 80%.

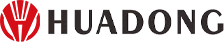

Amorphous Alloy Dry-Type Transformer Model:

Amorphous Alloy Dry-Type Transformer Characteristic:

Low loss: The no-load and load losses of amorphous alloy dry-type transformers are relatively low. Its no-load loss has decreased by 75% compared to the standard value specified in GB/T10228, and its load loss has also been reduced compared to traditional transformers.

High energy efficiency: Due to the stronger magnetic permeability and lower losses of amorphous alloy materials, the energy conversion efficiency of amorphous alloy dry-type transformers is higher.

Easy maintenance: The aluminum oxide layer of amorphous alloy dry-type transformers does not fade, fall off, or paint, reducing maintenance complexity and extending service life.

Good stability: Amorphous alloy materials have high saturation magnetic induction strength, low coercivity, and good temperature stability, which enables transformers to maintain stable performance even in high temperature environments.

Strong insulation performance: Amorphous alloy dry-type transformers use insulation materials such as epoxy resin, which have good electrical insulation performance and mechanical strength.

Amorphous Alloy Dry-Type Transformer Application:

Factory power distribution system: Amorphous alloy dry-type transformers can be used for the internal power distribution system of the factory, providing stable and reliable power supply for various production equipment. Its high-efficiency and energy-saving characteristics help reduce the energy consumption cost of factories and improve production efficiency.

Mining power system: In the mining environment, the stability and reliability of power supply are crucial. Amorphous alloy dry-type transformers can adapt to harsh environmental conditions in mines, such as high temperature, humidity, corrosion, etc., ensuring the stability of power supply. At the same time, its efficient and energy-saving characteristics also help reduce the energy consumption cost of mines.

Power supply for manufacturing equipment: In manufacturing, various production equipment requires stable and reliable power supply to ensure production efficiency and product quality. Amorphous alloy dry-type transformers can be used to provide power support for manufacturing equipment, and their high-efficiency and energy-saving characteristics help reduce energy consumption costs and improve production efficiency.

Amorphous Alloy Dry-Type Transformer Specifications

| Rated capacity KVA | Level 1 | Level 2 | Level 3 | Short-circuit impedance % |

|||||||||

| Amorphous alloy | Amorphous alloy | Amorphous alloy | |||||||||||

| Empty loss W | Load loss W | Empty loss W | Load loss W | Empty loss W | Load loss W |

||||||||

| B | F | H | B | F | H | B | F | H | |||||

| (100℃) | (120℃) | (145℃) | (100℃) | 120℃ | (145℃) | (100℃ | (120℃) | (145℃ | |||||

| 30 | 50 | 605 | 640 | 685 | 60 | 605 | 640 | 685 | 70 | 670 | 710 | 760 | 4 |

| 50 | 60 | 845 | 900 | 965 | 75 | 845 | 900 | 965 | 90 | 940 | 1000 | 1070 | |

| 80 | 85 | 1160 | 1240 | 1330 | 100 | 1160 | 1240 | 1330 | 120 | 1290 | 380 | 1480 | |

| 100 | 90 | 1330 | 1415 | 1520 | 110 | 1330 | 1415 | 1520 | 130 | 1480 | 1570 | 1690 | |

| 125 | 105 | 1565 | 1665 | 1780 | 130 | 1565 | 1665 | 1780 | 150 | 1740 | 1850 | 1980 | |

| 160 | 120 | 1800 | 1915 | 2050 | 145 | 1800 | 1915 | 2050 | 170 | 2000 | 2130 | 2280 | |

| 200 | 140 | 2135 | 2275 | 2440 | 170 | 2135 | 2275 | 2440 | 200 | 2370 | 2530 | 2710 | |

| 250 | 160 | 2330 | 2485 | 2665 | 195 | 2330 | 2485 | 2665 | 230 | 2590 | 2760 | 2960 | |

| 345 | 195 | 2945 | 3125 | 3355 | 235 | 2945 | 3125 | 3355 | 280 | 3270 | 3470 | 3730 | |

| 400 | 215 | 3375 | 3590 | 3850 | 265 | 3375 | 3590 | 3850 | 310 | 3750 | 3990 | 4280 | |

| 500 | 250 | 4130 | 4390 | 4705 | 305 | 4130 | 4390 | 4705 | 360 | 4590 | 4880 | 5230 | |

| 630 | 295 | 4975 | 5290 | 5660 | 360 | 4975 | 5290 | 5660 | 420 | 5530 | 5880 | 6290 | |

| 630 | 290 | 5050 | 5365 | 5760 | 350 | 5050 | 5365 | 5760 | 410 | 5610 | 5960 | 6400 | 6 |

| 800 | 335 | 5895 | 6265 | 6715 | 410 | 5895 | 6265 | 5715 | 480 | 6550 | 6960 | 7490 | |

| 1000 | 385 | 6885 | 7315 | 7885 | 470 | 6885 | 7315 | 7885 | 550 | 7650 | 8130 | 8760 | |

| 1250 | 455 | 8190 | 8720 | 9335 | 550 | 8190 | 8720 | 9335 | 650 | 9100 | 9690 | 10370 | |

| 600 | 530 | 9945 | 1055 | 11320 | 645 | 9945 | 10555 | 11320 | 760 | 11050 | 11730 | 12580 | |

| 2000 | 700 | 12240 | 13005 | 14005 | 850 | 12240 | 13005 | 14005 | 1000 | 13600 | 14450 | 15560 | |

| 2500 | 840 | 14535 | 15445 | e605 | 1020 | 14535 | 15445 | 16605 | 1200 | 16150 | 17170 | 40A50 | |

lf you have any further requests or questions

TECHNICAL & SALES SUPPORT

If you have any questions, please contact us. We’ll do our best to help.